Jwell Machine Face Mask PP Melt Blown Machine

Model No.︰-

Brand Name︰Jwell machine

Country of Origin︰-

Unit Price︰CNY ¥ 120000 / pc

Minimum Order︰1 pc

Product Description

Jwell Machine Face Mask PP Melt Blown Machine

I. Overview:

Meltblown non-woven fabric is a kind of rapid development in the production of non-woven fabric. It is known as the one-step polymer production process with the shortest process abroad. Its products have many apparent advantages, such as high filtration efficiency, low resistance, flexibility, and the network can self-bond and bond. Therefore, it uses in various countries, and its main uses are medium-efficiency and sub-efficient filtration, including air filtration and acid destruction. Liquid filtration food hygiene filtration, industrial dust mask manufacturing, etc., can also be used as medical and sanitary supplies, industrial precision wipes, thermal insulation materials, oil-absorbing materials, battery separators, imitation leather base cloth and so on. In many ways, its performance is better than similar products of traditional textiles. With the continuous development of post-processing technology, the application fields of melt-blown non-woven fabrics will be more extensive.

With years of R & D experience, Jwell Extrusion Machinery Manufacturing Co., Ltd. can provide customers with 200mm-3200mm melt-blown production lines of various widths. The quality and energy consumption of products is close to the advanced level of similar foreign products.

2. Technical Features of Jwell machine M Meltblown Nonwoven Fabric Production Line:

1. Adopt special hanger type and gas equalizing type spinning die with independent intellectual property rights to distribute the melt evenly.

2. The air pressure of the air nozzle is stable, the airflow on both sides is symmetrical, and the airflow in the width direction is uniform.

3. The air gap width is easy to adjust.

4. A specially designed hot air flow heating device has good heating efficiency and excellent heat exchange efficiency, with low energy consumption.

5. The receiving distance is adjustable, and the receiving form (flat net receiving and roller receiving) can replace easily.

6. Uniform fiber fineness and cloth surface.

7. The electret treatment makes the melt-blown cloth have a good filtering effect.

3. Technical Parameters of Jwell machine M Meltblown Nonwoven Fabric Production Line:

1. JW1600 (door width 1600mm) production line, technical parameters

Gram weight range 10-80 grams / square meter design maximum speed 100 meters / minute production capacity 600 tons / year

2, JW2400 (door width 2400mm) production line, technical parameters

Gram weight range 10-80 grams / square meter design maximum speed 100 meters / minute production capacity 1000 tons / year

3, JW3200 (door width 3200mm) production line, technical parameters

Gram weight range 10-80 grams / square meter design maximum speed 100 meters / minute production capacity 1500 tons / year

4, JW4200 (door width 4200mm) production line, technical parameters

Gram weight range 10-80 grams / square meter design maximum speed 100 meters / minute production capacity 2000 tons / year

Fourth, five common application areas of melt-blown non-woven fabrics:

1. Application in the field of air purification: used in air purifiers, as a sub-efficient and high-efficiency air filter element, and used for coarse and medium-efficiency air filtration with high flow rates. It has the advantages of low resistance, high strength, excellent acid and alkali resistance, corrosion resistance, stable efficiency, long service life, and low price. There is no fluff in the gas purified by the filter material.

2. Application in the field of medical and health: the dust-proof mouth made of melt-blown cloth has small breathing resistance, no suffocation, and the dust-proof efficiency is as high as 99%. Its use in hospitals, food processing, mines, etc. that require dust and bacteria. The anti-inflammatory and analgesic film made by the products used in the workplace after special treatment has excellent breathability, no toxic and side effects, and is easy to use. SMS products combined with spunbond cloth usually use in the production of sanitary products such as surgical clothes and hats.

3. Liquid filter materials and battery separators: Polypropylene melt-blown cloth used in filter acidic and alkaline liquids, oils, oils, etc. It has outstanding performance, has been regarded as a good separator material by the battery industry at home and abroad, and widely used. The application not only reduces the battery cost, simplifies the process, but also dramatically reduces the weight and volume of the battery.

4. Oil-absorbing materials and industrial wipes: various oil-absorbing materials made of polypropylene melt-blown cloth can absorb oil up to 14-15 times its weight, widely used in environmental protection projects, oil-water separation projects, and besides, in industrial production, Can be used as a clean material

5. Thermal insulation material: The average diameter of the melt-blown ultrafine fibres is between 0.5 and 5m, the specific surface area is large, a large number of delicate pores formed in the cloth, and the porosity is high. A large amount of air is stored in this structure, which can effectively prevent heat loss, and has excellent thermal insulation. It used in the production of clothing and various insulation materials. Such as leather jackets, ski shirts, winter clothes, cotton village cloth, etc., it has the advantages of lightweight, warmth, no moisture absorption, excellent breathability, and no mildew.

V. Introduction of N95 / Medical / Civil Mask Material M Meltblown Nonwoven:

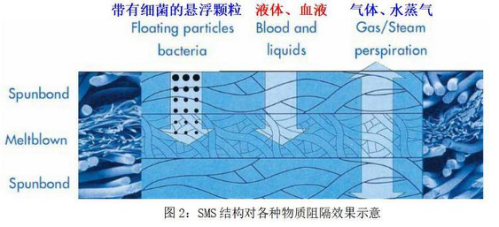

Masks are all made of polypropylene (PP, abbreviated as PP). Medical-surgical costumes are generally of the multi-layer structure, commonly referred to as SMS structure.

S in the mask layer represents spunbond fibre, the fibre diameter is relatively thick, about 20 microns (nm), two layers of spunbond texture mainly support the entire nonwoven fabric structure, has no noticeable effect on the barrier performance. The most important inside the mask is the barrier layer or melt-blown layer (M). The fibre diameter of the melt-blown layer is relatively thin, about 2 microns (M), so it is only one-tenth of the width of the spunbond layer, which is essential to prevent bacteria and blood from entering the spunbond segment.

Compare the fibres of the spun bond layer and the spray layer M to compare the shape of the texture and the hair. As we all know, The hair diameter is one-third, and the fibre close to the spun bond layer is 1/30 of the hair diameter. The spray layer is close to the M fibre diameter. Of course, more delicate fibres develop to ensure better antibacterial barrier performance.

As mentioned above, the thinner the M layer, the more able to prevent the entry of small particles such as bacteria, such as N95. It means that under normal circumstances, it can block 95% of small particles (0.3 microns). Under the condition of a gas flow rate of 85L / min, the national standard for a medical respirator is GB / T 19083. N95 is a 5-layer mask made of polypropylene nonwoven SMMMS, which can filter 95% of fine particles.

From the perspective of materials, the requirements of spunbond layer S and melt-blown layer M:

M layer: melt-blown layer, material requirements: high fluidity

S layer: spunbond layer, material requirements: high strength

With the global expansion of the new crown, China JWELL Intelligent Plastic Extrusion Machinery Co.,Ltd. (after this referred to as "Suzhou Jwell") actively responds to the national call and the needs of many old customers. With years of experience accumulated in the chemical fibre spinning and nonwoven industry, the organization R & D and production strength, strong introduction of polypropylene melt-blown nonwoven production line. As one of the world's well-known manufacturers of plastic extrusion equipment, Jwell Machinery is to solve the problematic situation that is hard to find in the world.

As we all know, the melt-blown cloth is the core material of medical protective masks, and it is also the key to fight the war against epidemic disease. Suzhou Jwell has provided 1300mm-3200mm extensive PP melt blown cloth production line through its technical advantages for many years, using high-quality core components, advanced production line technology and a high degree of automation. At present, more than 30 high-performance and high-yield production lines have been put into production and promised to deliver the entire production line within 60-70 days, which provides a security guarantee for customers to put into production and anti-epidemic protection work quickly.

Suzhou Jwell polypropylene melt-blown nonwoven production line has many advantages.

1. Professional screw design experience, good plasticization effect, stable performance, suitable for high output extrusion;

2. high-precision filtration system and melts metering system, real-time closed-loop control of extrusion pressure Stable;

3. The high-precision extrusion die head and spinneret assembly to meet the production of high-quality products;

4. Professional high-temperature-resistant belt-type web forming system, optimized design of negative pressure system;

5. Fully automated online cutting and winding system, high-speed operation and stability;

6. Use Siemens brand high-performance PLC integrated control system;

7. one-stop service, equipped with high-temperature calciner, electrostatic electret, vacuum cleaning and testing equipment.

Product Image